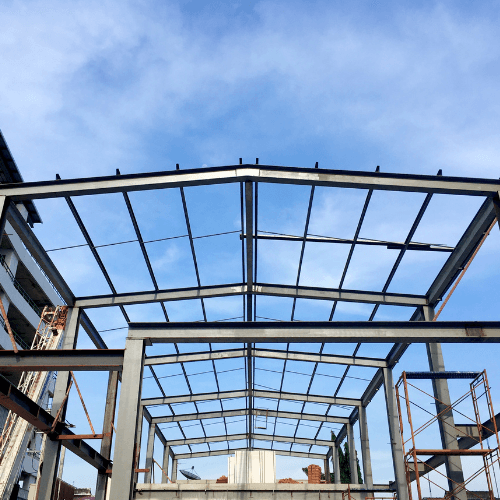

In the world of construction, steel buildings stand tall, sturdy, and economical. But when it comes to figuring out the cost, things can get a bit complex. Let's break it down into simple terms.

1. Design and Size: Just like buying clothes, the size matters. The bigger the building, the more materials you'll need, which means higher costs. Also, intricate designs or customizations can add to the price tag. Keeping it simple can help keep costs down.

2. Labor Expenses: Skilled workers are needed to build a steel structure, and their costs can vary depending on factors like location and project complexity.

3. Foundation: A sturdy building needs a strong foundation, and the type required can impact costs. Simple slab foundations might cost less than deep concrete foundations.

4. Permits and Regulations: Before building, permits from local authorities are needed, and these come with fees that add to the overall cost. Adhering to building codes and regulations is essential and might require additional expenses for inspections and compliance.

5. Additional Features: Features like windows, doors, insulation, or ventilation can enhance a steel building's functionality and comfort but can also increase costs.

6. Transportation and Installation: Getting steel beams and panels to the construction site isn't free. Transportation costs can vary based on distance and logistics. Assembling the structure also requires time and effort from skilled professionals.

7. Maintenance: While steel buildings have low maintenance needs, regular upkeep like painting or rust prevention may be necessary, adding to the overall cost over time.

In conclusion, understanding the factors influencing the cost of steel buildings is crucial for making informed decisions that fit your needs and budget.